A Closer Look

The structural design called for custom nodes to connect inclined and vertical mega columns at the base of a high-rise tower. These nodes had to resist significant prying forces, while still remaining practical to fabricate and weld.

We didn’t know what these plates were going to look like, we only had some manufacturing constraints like making sure the distances to the edges were reasonable. It was the perfect case to use Grasshopper because we needed to generate several iterations quickly.

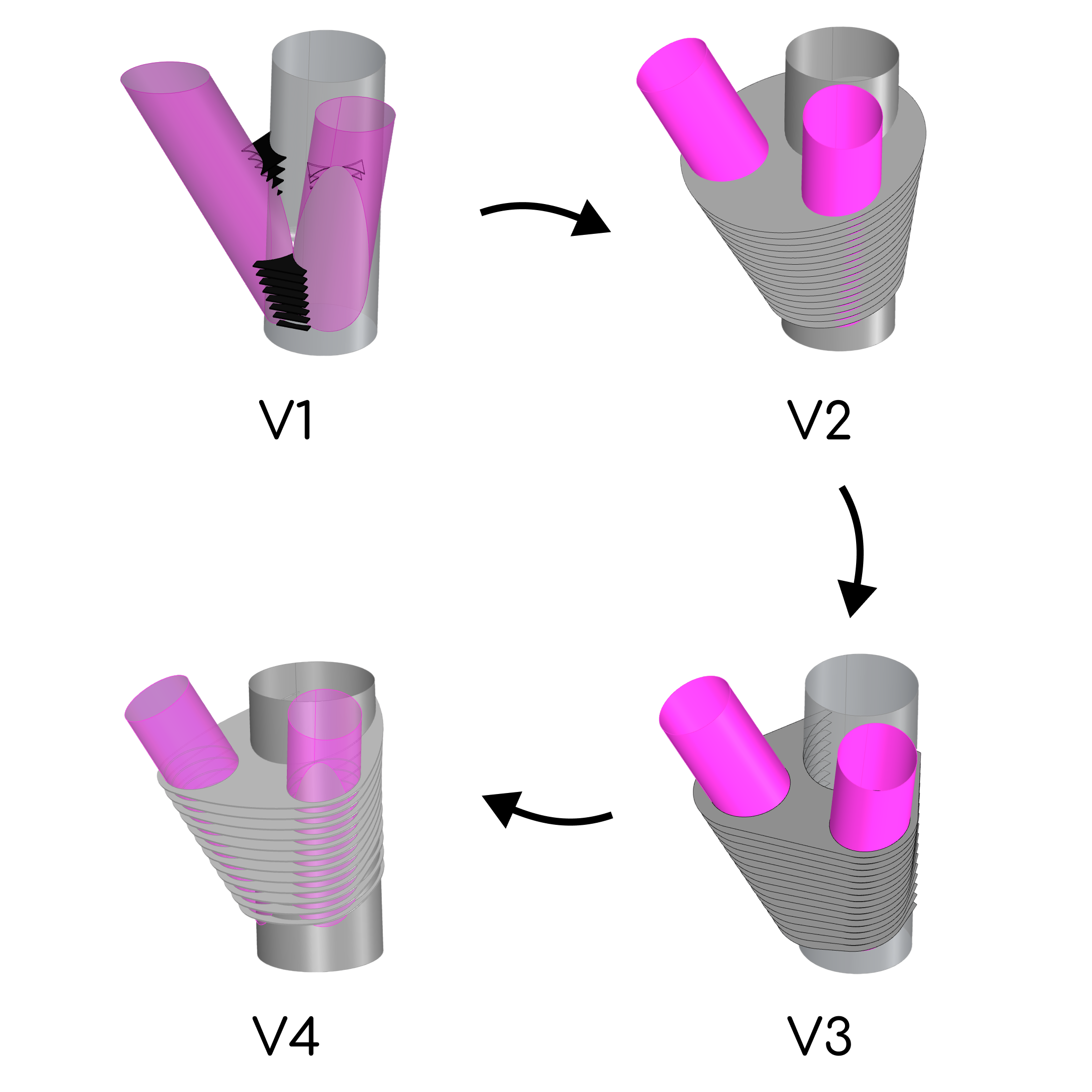

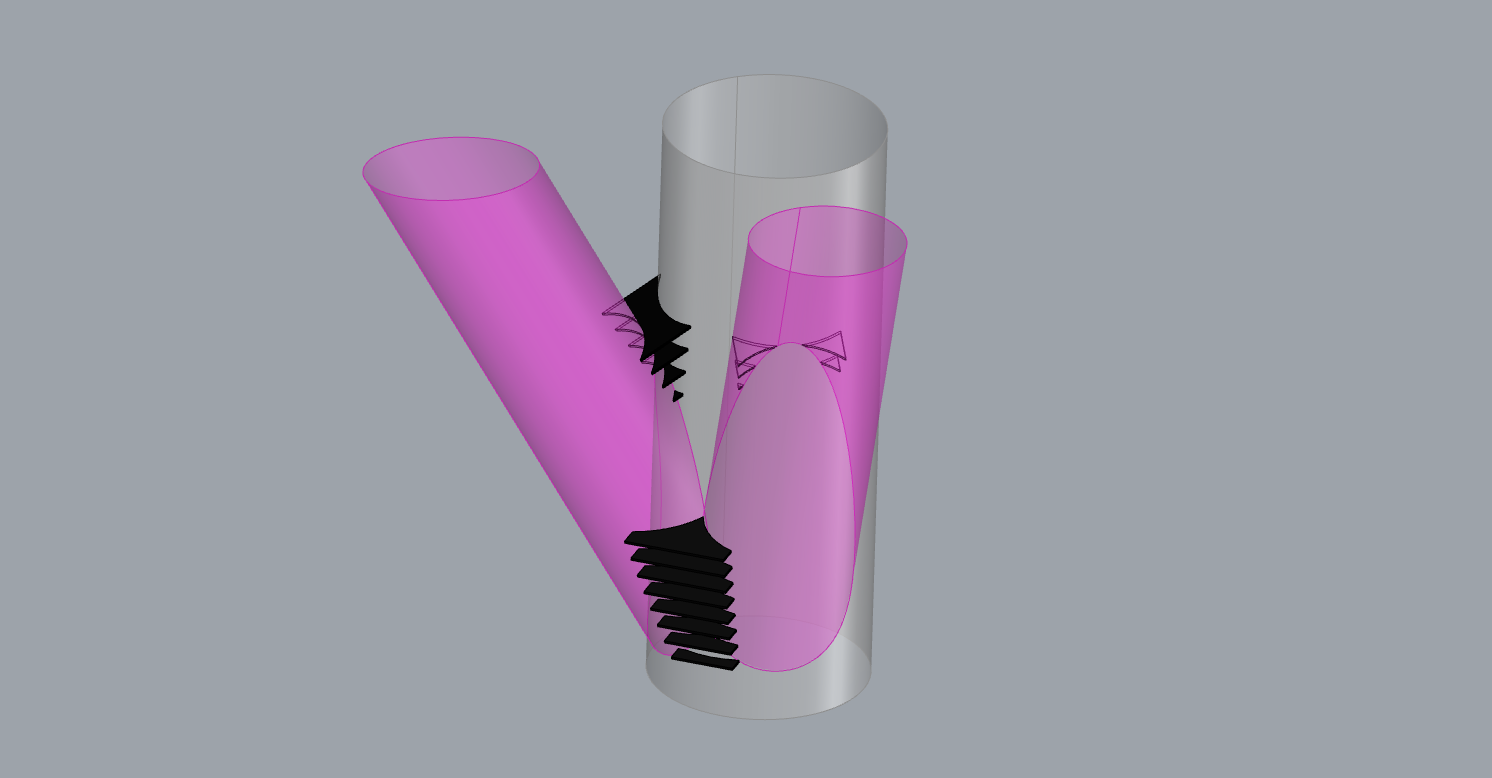

Iteration 1 - Pull Plates

Plates were placed between columns to “pull” them together. While it looked cool and really “optimised”, the plate shapes were too irregular to fabricate or weld properly.

Small Plates that pulled the columns together

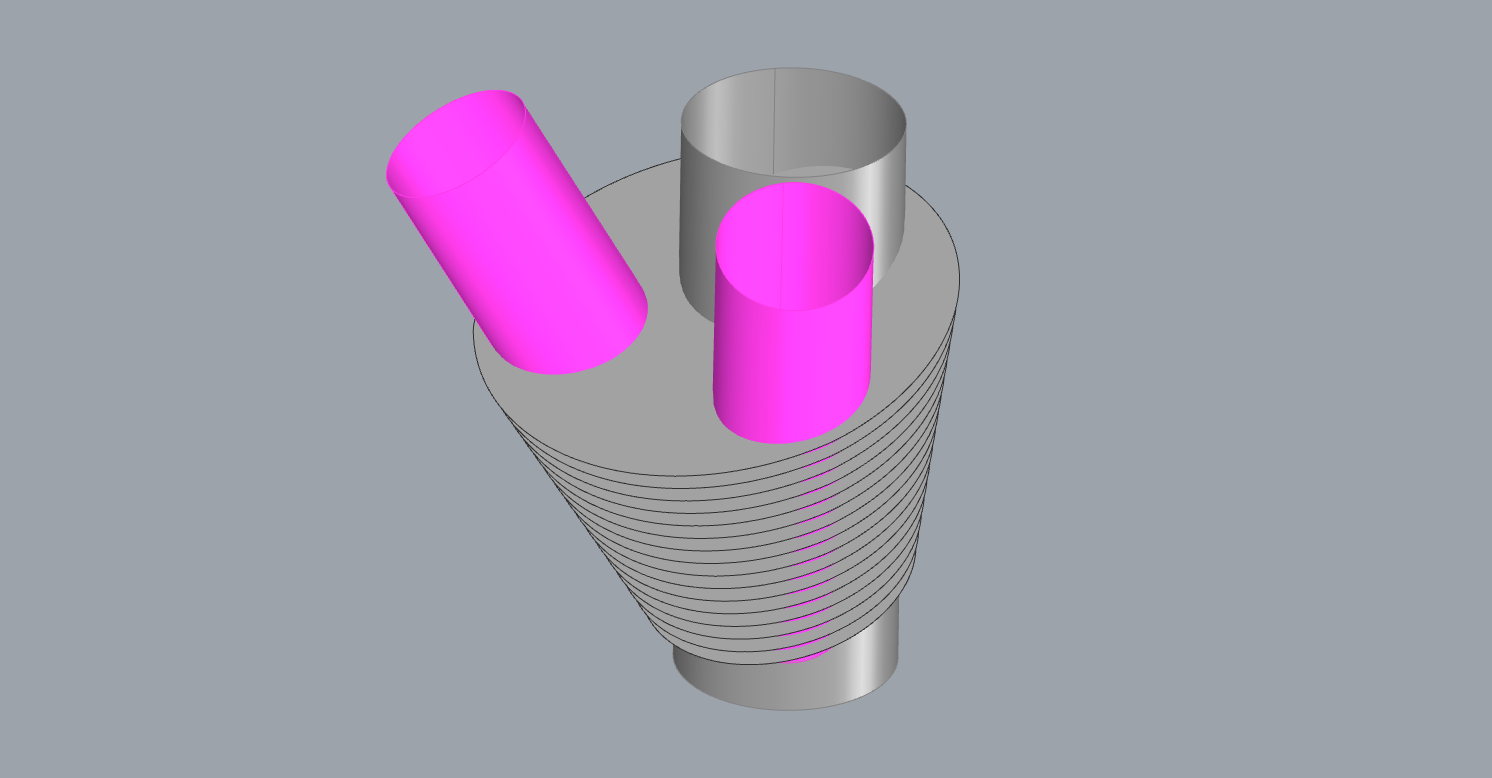

Iteration 2 - Enclosing Rings

Then instead of plates, we tried just fitting circles through it, hoping to ease manufacturing. The problem was that we wasted a lof of steel with this option.

I call this variant the cone of shape

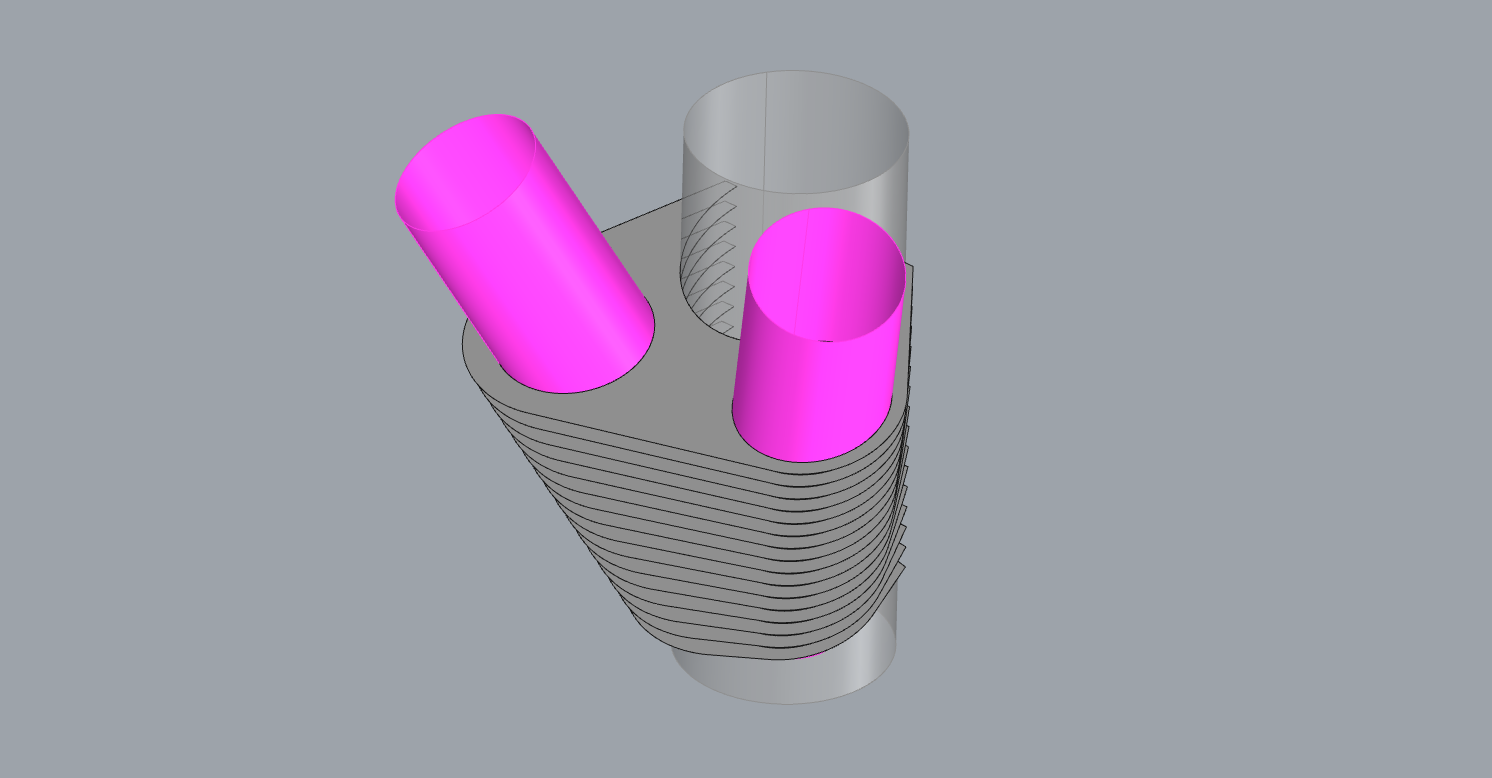

Iteration 3 - Straight Edges

Then we tried to create a more regular shape by maintaining the edge distances from the columns but the straight edges presented too much stress for the node to handle

We're almost there because the plates are starting to look reasonable now

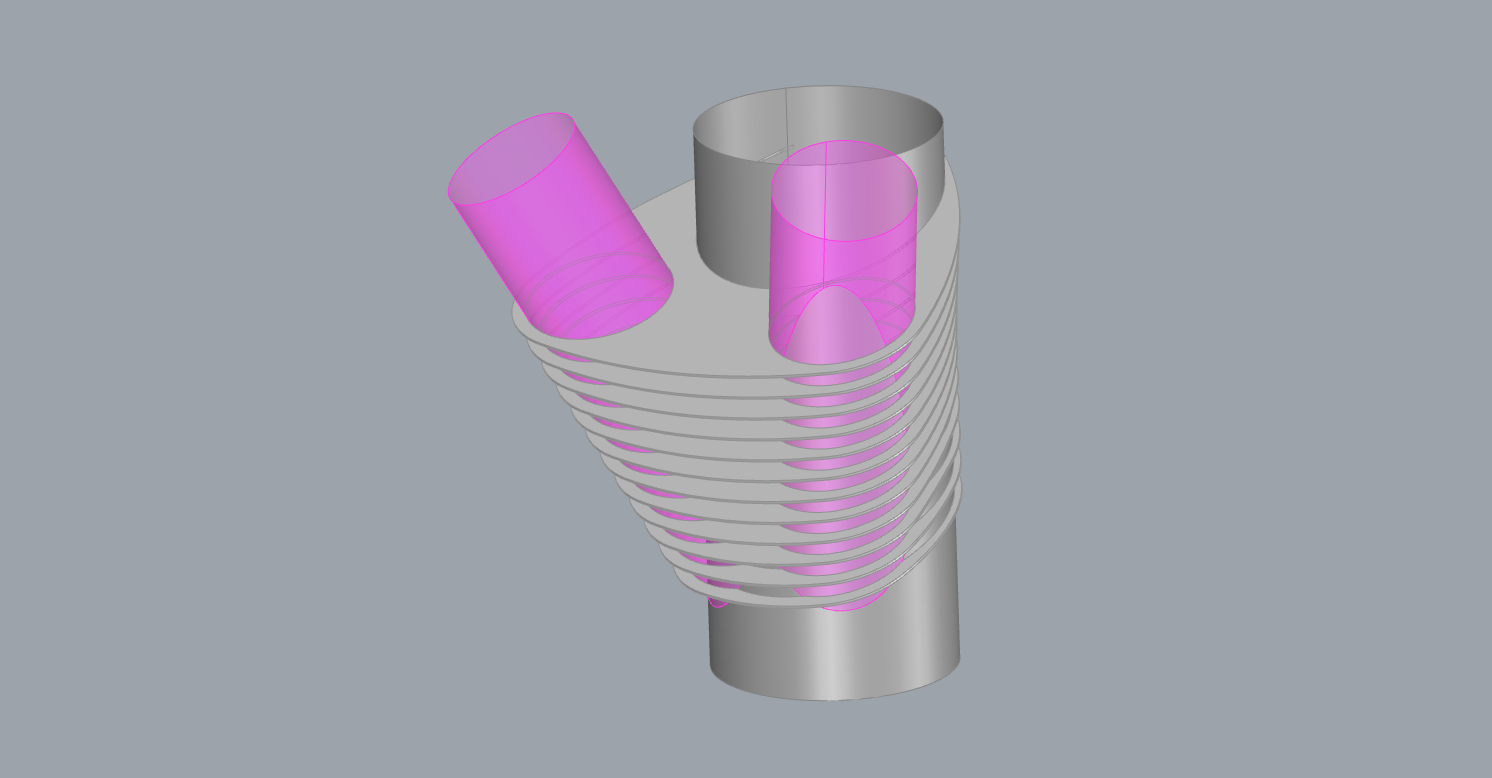

Iteration 4 - Hybrid Rings

Learning from all the past iterations, we decided to combine all the features of iteration 2 & 3. It was a mix of best fit circles with arcs between them to save on steel.

The final model

I even have a section in the script where we played around with the angle to generate the arcs

Using angles to blend between the circles

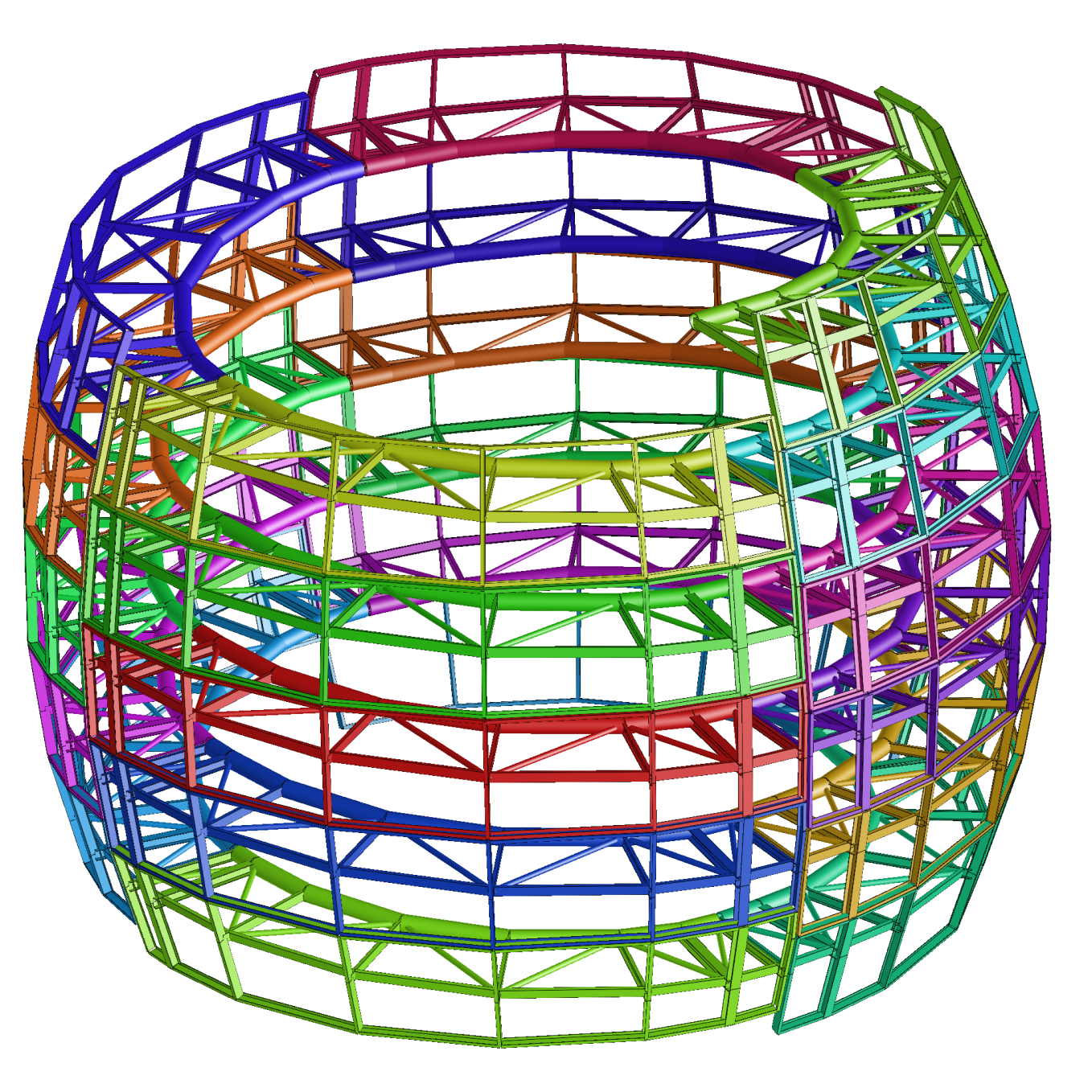

Once the geometry was resolved, it was prepared for detailed structural analysis. The Grasshopper model was exported as a SAT file, then brought into ABAQUS for finite element modelling.

The analysis confirmed the design met performance requirements, the final geometry was approved for fabrication and construction.