A Closer Look

Many computational models look great, the continuous curves surfaces, smooth geometry and complex shapes. But the reality of making these models is a lot harder than it seems.

Eventually, every concept model needs to be rationalized into something that can be built. The goal then is to keep the rationalization as close to the original shape as possible.

The key to doing this successfully is to work with how the geometry wants to be naturally broken up.

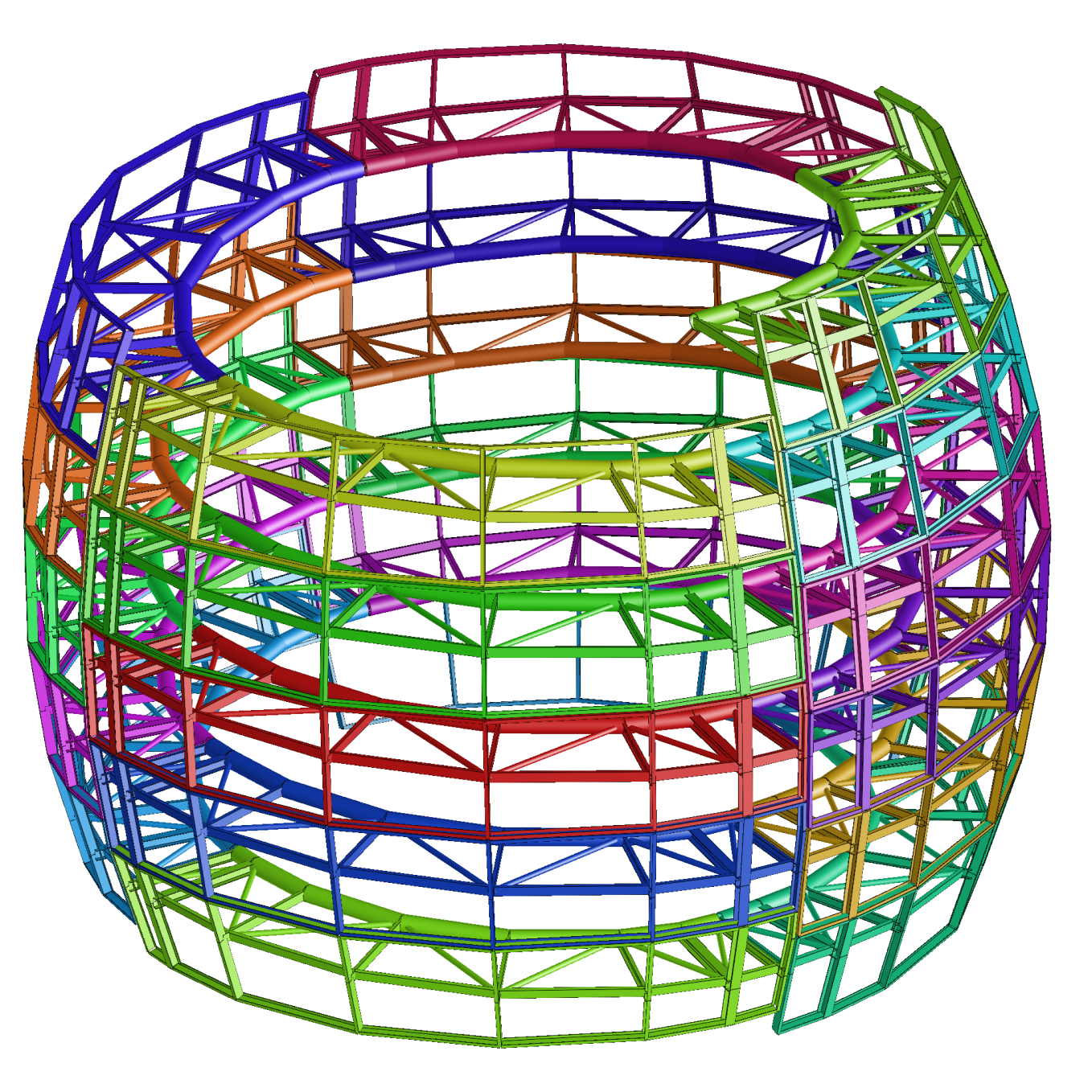

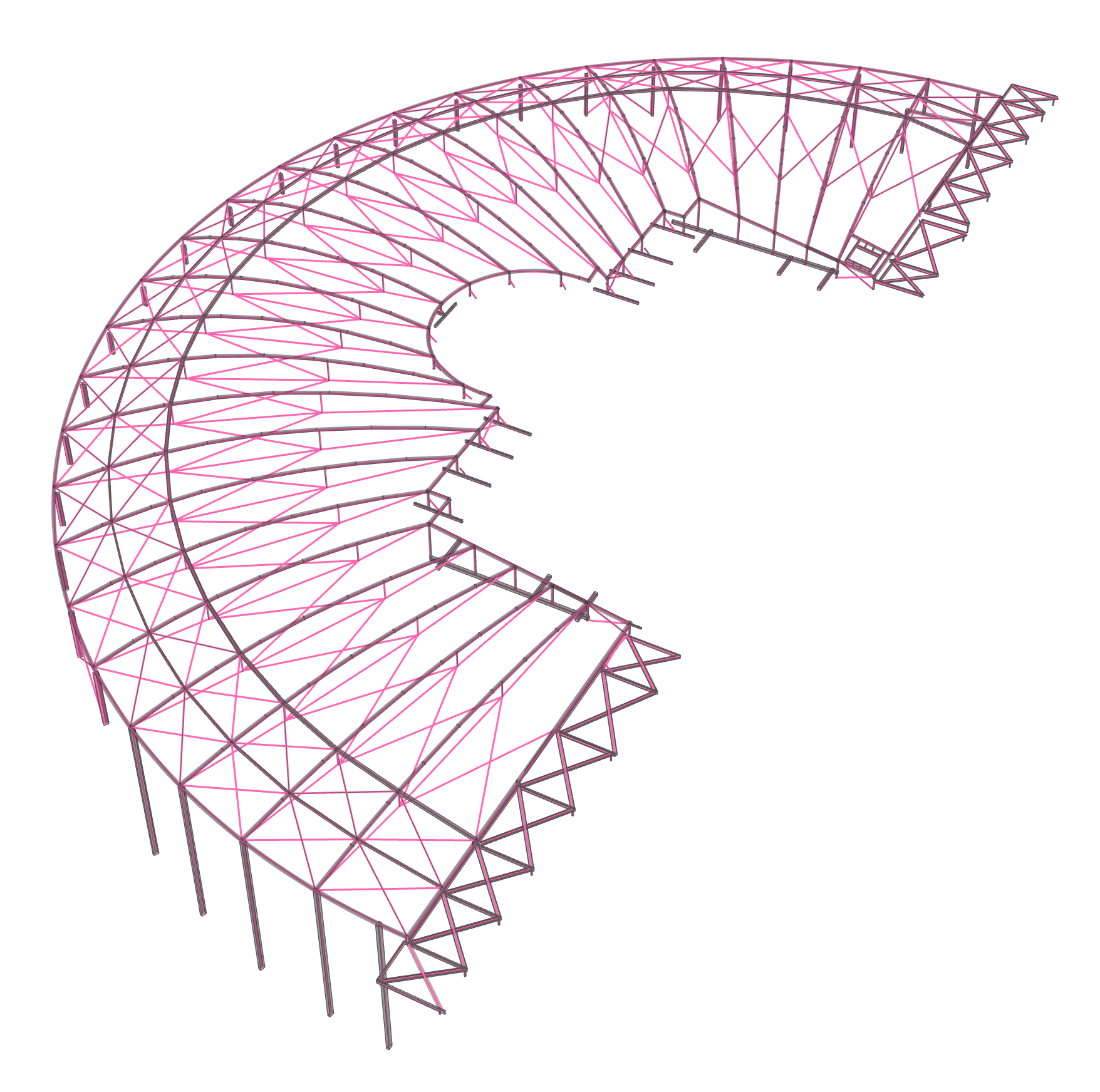

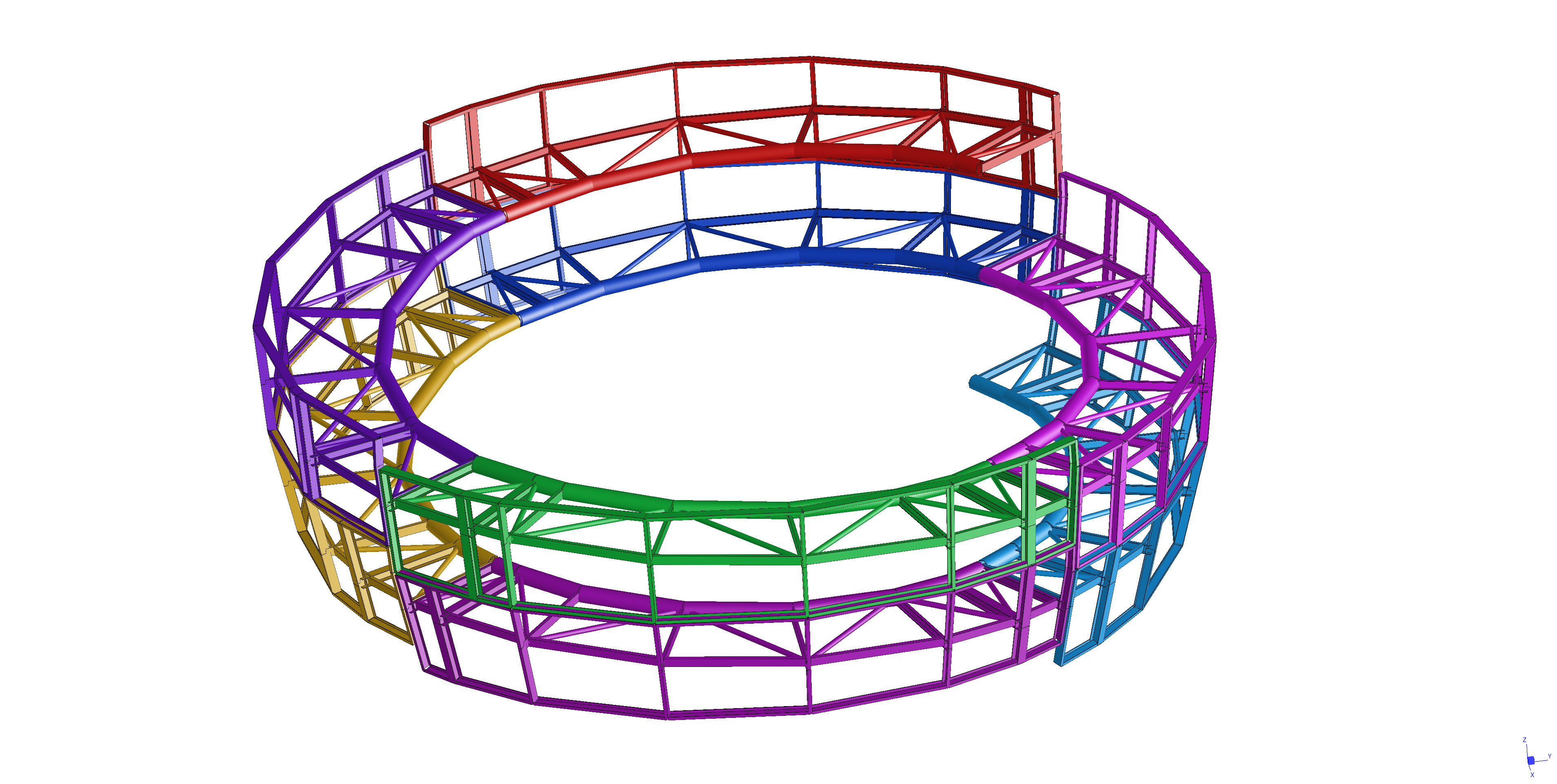

In this project, the design was circular in plan with a spiraling ramp running through it. While it looks amazing, it’s also a massive construction challenge. The approach then was to break the model down into discrete modules.

Rationalised Modules

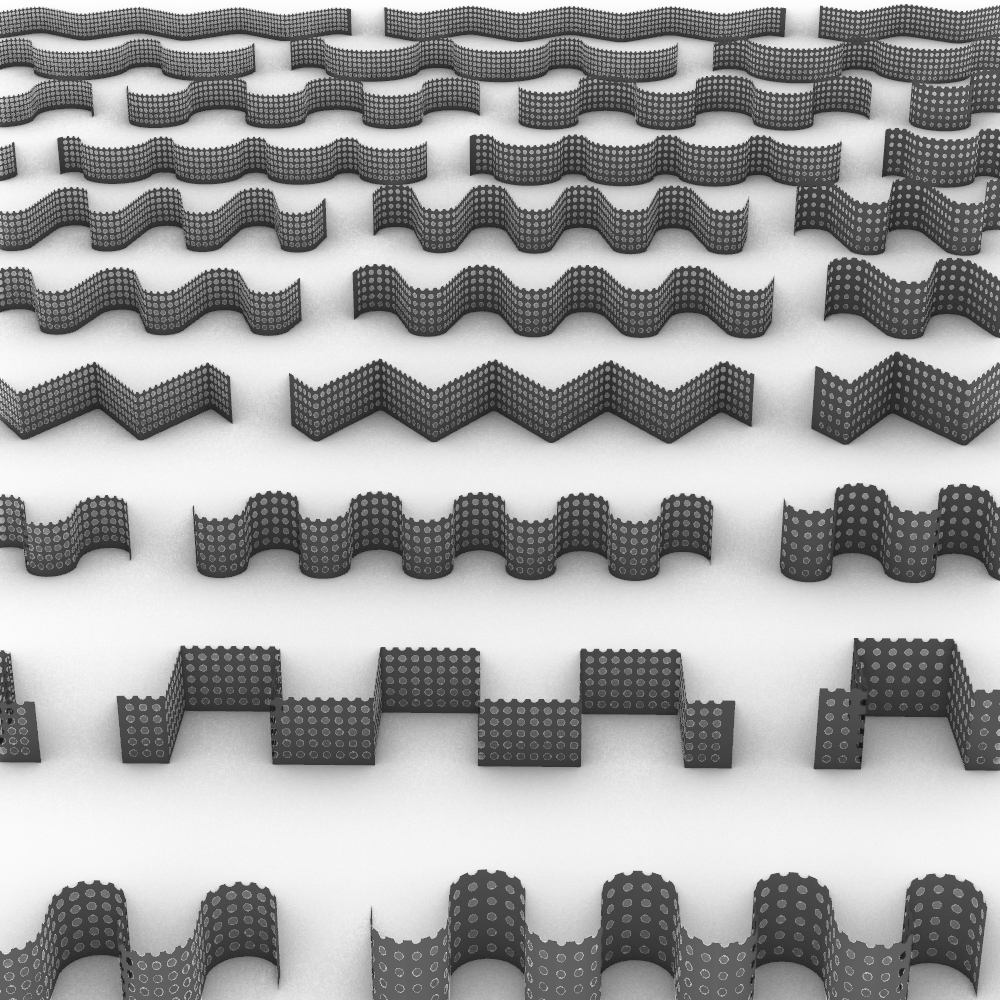

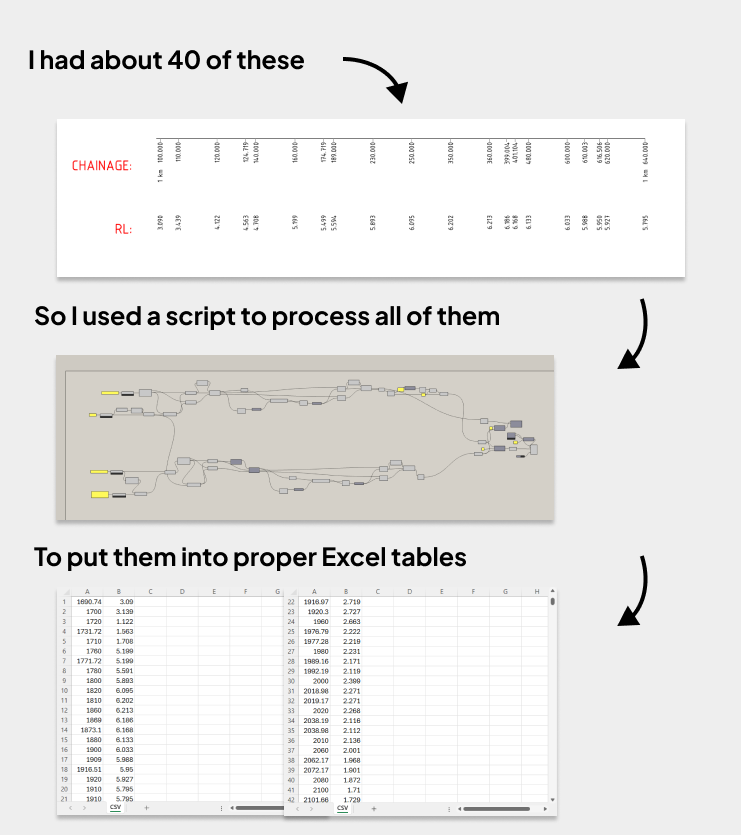

We explored the idea of using prefabricated modules that could be assembled off-site and lifted into place. This gave us more control over manufacturing tolerances and allowed for easier installation. The parametric workflow I created meant that we could adjust the parameters of the modules without having to remodel from scratch again. This allowed us to explore different options of what these modules would look like.

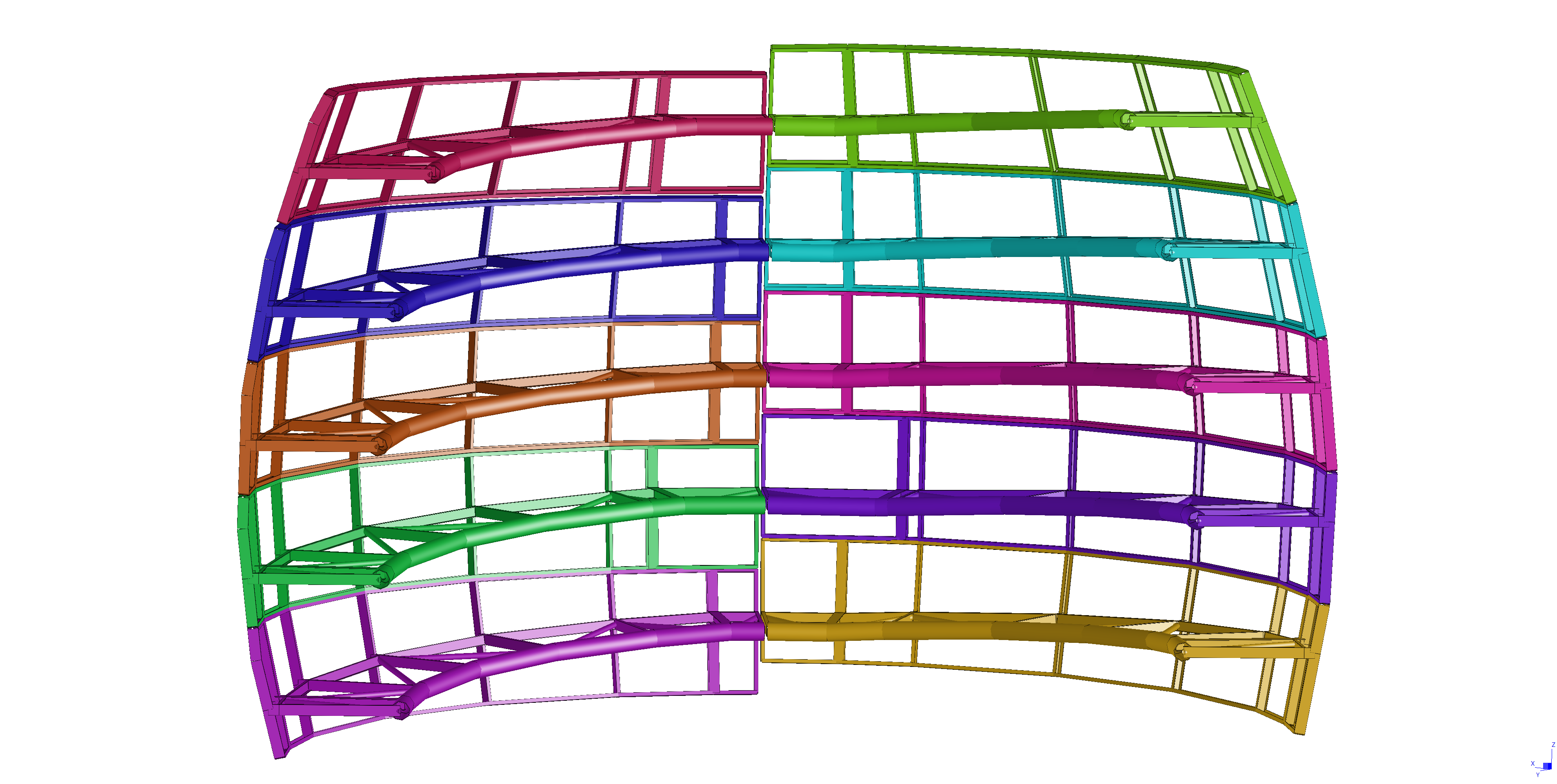

But modularity wasn’t enough. The geometry of the model meant that each module varied slightly in length and shape. The workflow I created had to allow for this variability, adapting to the geometry while still enforcing rules about connection locations, member spacing, and vertical supports. Especially since the ramp intersected the modules at different locations.

Modules showing some variation between them

The landings of the ramp provided a natural way to break the model into modules. From there, we divided the structure radially to define each module.

image of the super zoomed in modules.

This approach allowed us to retain the original architectural intent while making the structure feasible to fabricate and construct.